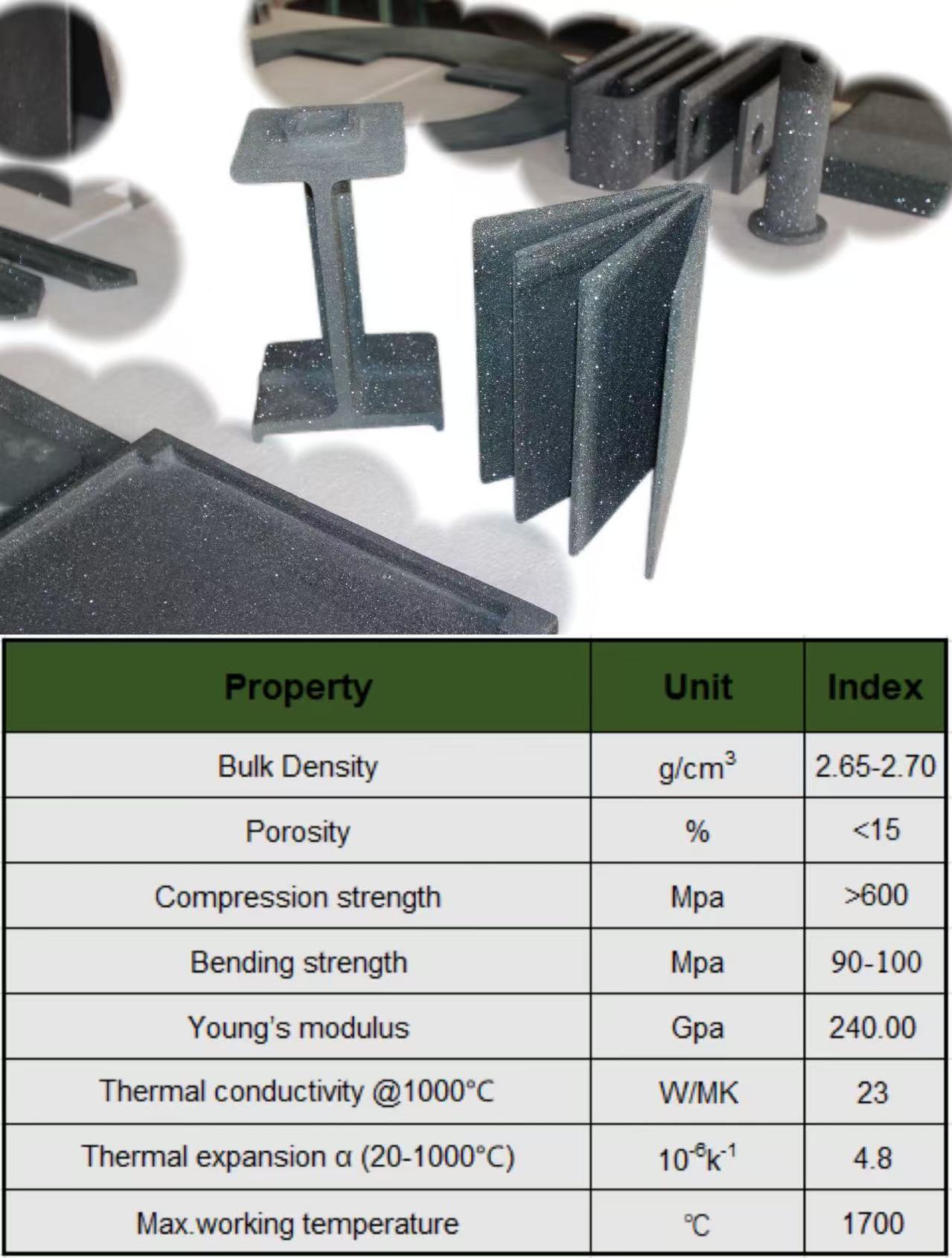

SNSiC is manufactured using premium-grade silicon carbide (SiC) combined with silicon nitride (Si3N4). The material is formed through slip casting or pressing techniques and fired in a nitrogen-rich atmosphere.

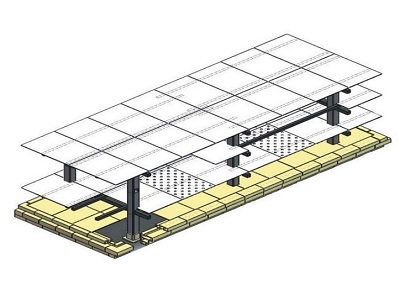

Key Features: • Exceptional load-bearing capability with excellent bending strength and compression strength • Excellent thermal conductivity and low thermal expansion coefficient • Operating temperature up to 1,500°C with high resistance to thermal shock. • Resistant to oxidation, corrosion, and chemical degradation, ensuring extended operational lifespans. Energy Saving: • Lightweight design reduces kiln car weight by 30–50%, significantly lowering energy consumption and CO₂ emissions. Applications: • Sanitary Ware and Tableware: Ideal for lightweight, high-efficiency kiln furniture such as setters and supports. • Industrial Sectors: Suitable for non-ferrous metal casting, galvanizing, fuel cells, and high-temperature processes requiring dimensional stability.

GMS Industrial Supplies Co., Limited

GMS Industrial Supplies Co., Limited